Through the earth’s water cycle, the planet’s fresh Water and Ocean are inextricably linked. Ninety-seven percent of the earth’s water is in the ocean and the ocean supplies almost all the water that falls on land as rain and snow. Of the 3% that is fresh water, two thirds are frozen, one-third is groundwater and a mere 0.3% remains as accessible surface water.

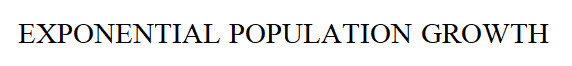

Of available renewable freshwater resources, about 54% is already appropriated by humanity for various uses – irrigated agriculture (70%), industry (22%) and domestic use (8%), and water withdrawals are projected by 2025 to increase by 50% and 18% in the developing and developed world, respectively.

Integrated Water Resources Management (IWRM), which incorporates issues of equity, efficiency and environment, is widely accepted as the path forward towards sustainable use of our precious water resources, but much remains to be done to put IWRM concepts into action.

Currently, just under 900 million people lack access to safe water and over 2.7 billion lack access to basic sanitation.

The impacts of low access to water and sanitation represent a substantial drag on socioeconomic development in many countries.

As much as 40% of the world oceans are considered as ‘heavily affected’ by human activities, including pollution, depleted fisheries, loss of coastal habitats such as coral reefs, mangroves and sea grasses, and by aquatic invasive species.

River Bank Filtration ( RBF)

Why RBF:

- surface water as a source for drinking water is gradually increasing.

- groundwater generally has the advantage of a good hygienic and consistent quality compared to surface water.

- abstraction of river bank filtrate enhances the infiltration of river water compared to the natural situation.

- RBF facilities helps towards a sustainable water resources management.

- Maximum flood proof RBF system by sufficient elevation

- RBF systems for potable water supply is a sustainable alternative to

- direct abstraction of surface water

- followed by constant conventional post-treatment

The biggest advantage of hydro energy is that essentially no carbon dioxide or other harmful emissions are produced once a hydro power plant is in operation.

A micro hydro power = < 100 kW

Mini hydro power = 100 – 2000 kW

CALA CASA SL appoints KRIVA ROCHEM

CALA CASA is a SPANISH-based company , a Designer and Promotor for Energy and Seawater Desalination solutions collaborating closely with experts in the fields of research, design, technology and construction management.The firm was founded in 1989.

Our company CALA CASA is linked with Kriva Rochem and their team of experts involved in Patents and a continuous and ongoing effort in distinctively labeling innovative water treatment concepts.

The business Line Water Technology offers the full range of design, engineering , construction and supervision for delivering domestic and industrial water treatment plants.

![]()

Project:

“WELL WATER TREATMENT SYSTEM”

Based On :

KRIVA – ROCHEM Freshwater Generator

System with TRIPLE TS Modules

System with TRIPLE TS Modules

Table of contents

- Introduction

- Functional description

- Pre-filtration

- PLC – Programmable logic controller

- Desalination Module

- Applied technology

- Membrane cushion

- Membrane cleaning

- Process Control

- Post treatment

- System performance

- Scope of Supply

- Out of scope

- Unit Installation and Transport

- Warranty liability

1. Introduction

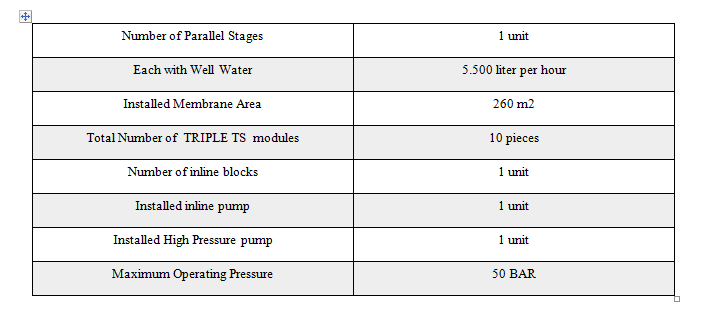

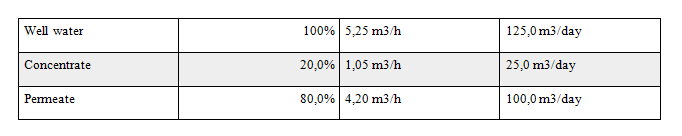

Given the conductivity and the requested discharge parameters with a total Raw Water Capacity of 125 m3/day and a Recovery Rate of up to 80% we are pleased to offer you a One Stages System for the treatment of Well Water.

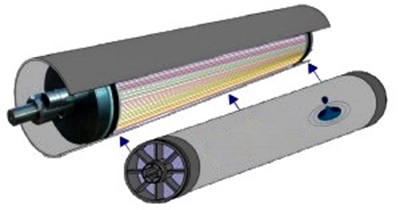

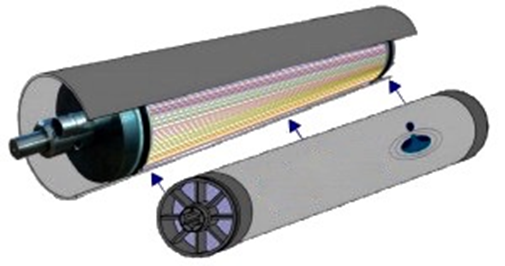

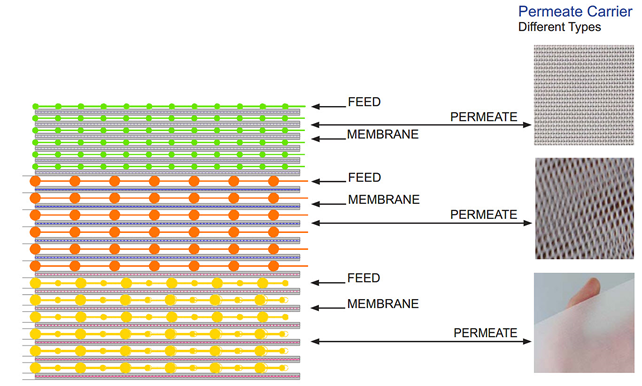

The Osmosis Plant that can produce naturally pure potable water. The quality of the produced water will be in accordance to the latest requirements of the WHO.The KRIVA- ROCHEM Reverse Osmosis Freshwater Generators are using specially developed spiral wound TRIPLE TS Desalination Modules. The technology is based on semi-permeable membranes , where water can pass the membranes, but ions and bigger molecules like organic substances can’t pass and are rejected. Consequently , the well water is separated in a clean water stream ( the permeate) and a highly concentrated reject ( the concentrate). The significant difference to conventional spiral round modules is that KRIVA – ROCHEM combines different feed channels, permeate carriers and membranes in one module element.

Triple TS Membranes

2. Functional description

Pre-filtration

PLC – Programmable logic controller

Desalination Module.

Technical Design of the RO Stage:

All valves,pumps and measuring devices which are necessary for system operation are installed in this stage.The RO- unit operates at 25 – 45 Bar. The operating pressure depends on the pollution level of the membranes and is adjusted by the measured permeate flow in the collecting pipe. The pressure regulation with the motor control valve keeps the recovery rate of the system. The permeate of the well water can be transferred to further treatment systems but the back pressure shouldn’t be higher than 2.0 bar.

Applied Technology.

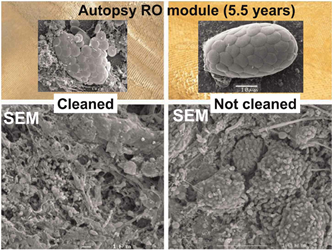

The advantage of the “open channel modules” is the avoidance of non-reversible fouling on the membranes during the process, as long as the system is operated in accordance to our manual. This means that the right parameters are adjusted, the correct chemicals are used and the process is kept under control.

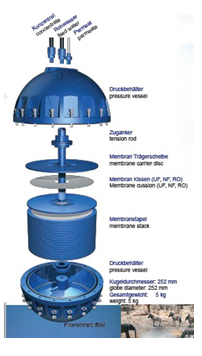

Membrane cushion

For different applications from different materials. The membrane cushion is made up with a sheet known as the permeate carrier. This permeate carrier is sandwiched between two membranes. The outer diameter is sealed by ultrasonic welding of the three ore more sheets together.

Especially, this module includes 3 times membranes more than the existing modules so it has the power of the three existing ones.

Membrane Cleaning

During the reverse osmosis process a fouling layer is formed on the membranes by organic compounds in the raw water. When the permeate flow is reduced by fouling layers on the embrane, a cleaning cycle is necessary to remove the fouling and to restore the performance on the membranes. For the cleaning cycle the normal operation stops, the concentrated solution in the system is removed and permeate is transferred into an internal cleaning tank.Chemical cleaner is added into this tank and this solution is heated and circulated in the system to remove fouling and scaling layers from the membranes. After cleaning the normal process can continue.

After approximately 600 to 800 hours of operation the unit demands a membrane cleaning. Cleaning is initialised by a few manual operation steps like switching of valves and filling of cleaner into the cleaning tank. The cleaning sequences are automatically controlled by the PLC.

For the cleaning procedure only harmless cleaning solutions will be used to remove fouling or other scaled deposits. The cleaning solutions belong to low class IMO-codification.

Process Control

For process control a data-recording software collets the operating parameters. This shows the parameter during operation and the totale recovery rate is continuously calculated. Another advantage of this software is the exact knowledge about the process situation which supports the maintenance of the system.

Post treatment

The offered KRIVA- ROCHEM Freshwater Generator include a de-acidification filter as post treatment for the re-hardening and pH increase of the permeate.

3. System performance

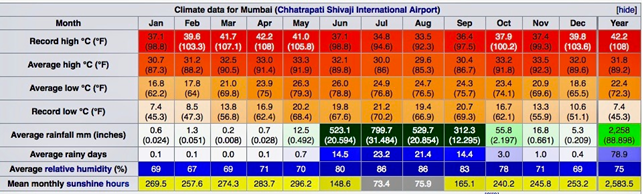

Temperature effect :

It must be kept in consideration that besides the pressure effect the permeate flow of each reverse osmosis membrane also depends on the temperature. This system has been quoted based on feed temperature of 20° C.

With increasing temperature the permeate flow increases

With decreasing temperature the permeate flow decreases

As a general rule the flow reduction can be calculated with 2 – 3 % per °C temperature reduction at constant pressure.

As this behaviour is not linear, at temperature > 15°C the reduction is lower , but below 15°C the permeate flow reduction should be calculated with 3% per °C

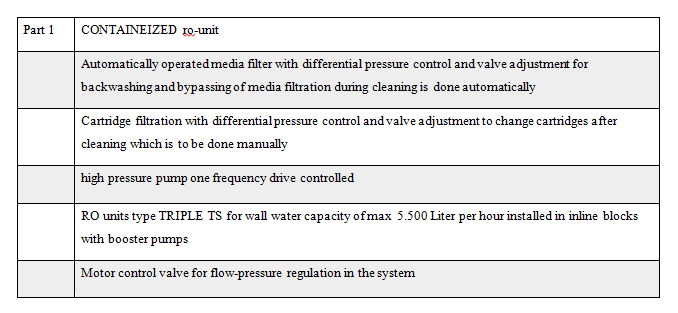

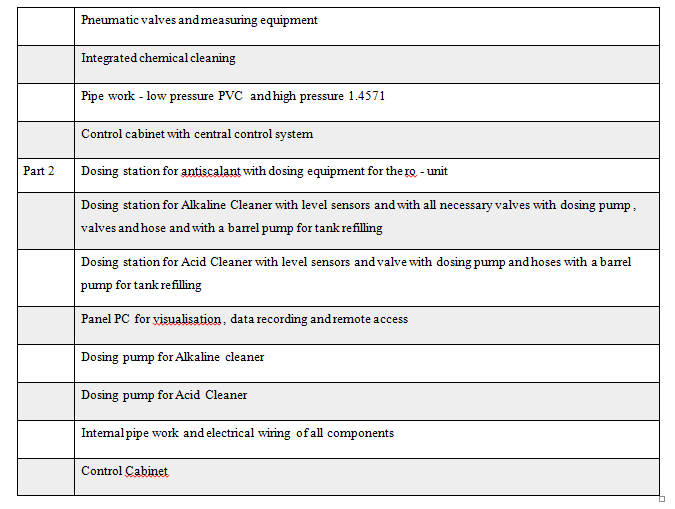

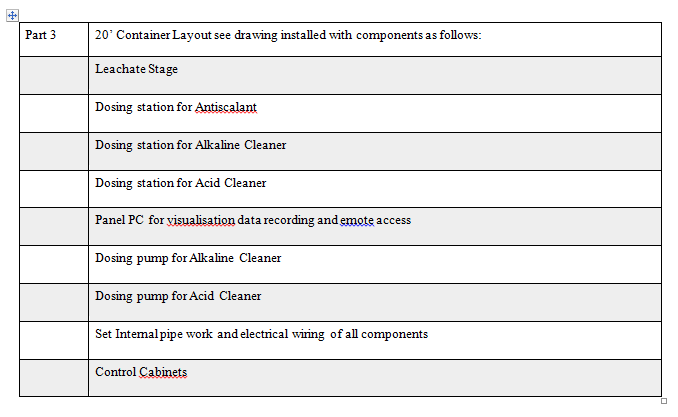

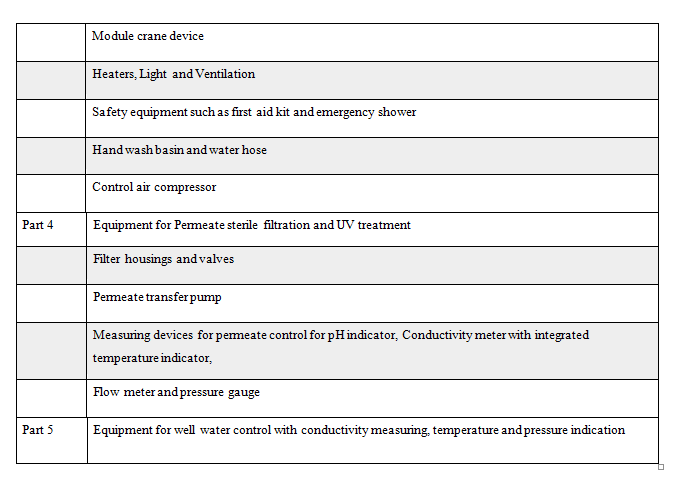

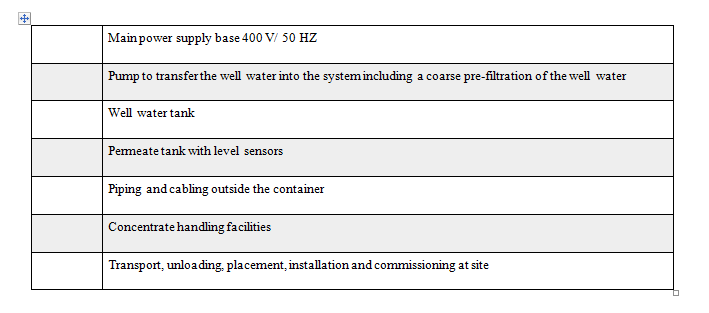

4. Scope of Supply

5. Out of Scope

6. Unit Installation and Transport

Apart Well Water Transfer from the source to the RO- system, the well water system is fully containerised and the interfaces for the connecting pipe work are located on one of the containerised sides.

The system is tested with a solution based on Sodium Chloride before delivery.

During this internal Factory Acceptance Test (FAT) all parts of the hardware and software are checked and notes are fixed in a factory Acceptance Test-Protocol.

Every customer is very welcome to join the factory Acceptance Test.

7. Warranty liability

The warranty period excluding wear parts is 12 months from start-up or 18 months from EXW Antwerpen ,whichever is the sooner The warranty period for the membranes is three years reaching in value throughout the period pro rata.

Water For Everybody

Safe drinking water for everybody

Solar – Nanofiltration 7.200 Liter per Day

CALA CASA Group

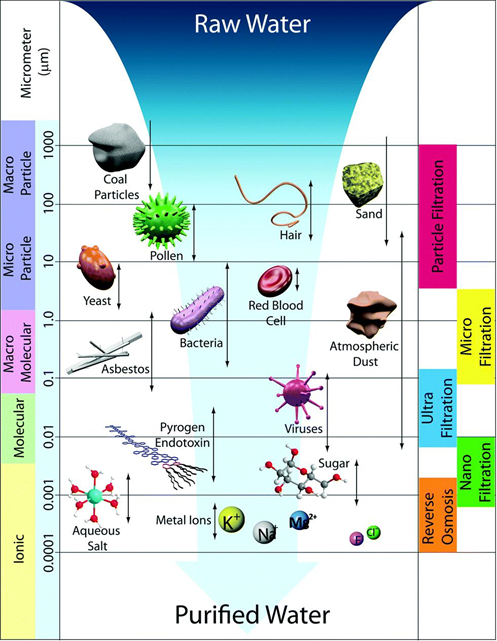

NANOFILTRATION

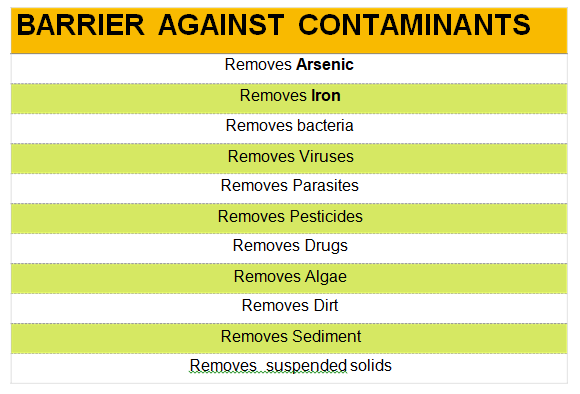

NF processes are currently preferred over traditional treatment methods for the following reasons:

- No chemicals required (aside from cleaning)

- Constant product quality regardless of feed quality

- Compact plant size

- Capable of exceeding regulatory standards of water quality, achieving 90–100% pathogen removal

The basic operating principle of nano-filtration uses a pressure induced separation of solutes from a solvent through a semi permeable membrane.

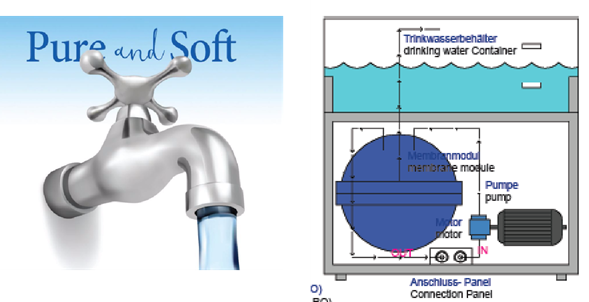

The CALA CASA GROUP Membrane Filtrator

The System is used to produce drinking water by membrane filters.The clean water is forced by the pump pressure to overflow the membrane filter. The membrane filter separates ions, macromolecular, solids, organic compounds, viruses, colloid, bacteria, etc. out of the raw water resulting a stream of drinking water of high purity. The separated impurities are returned with the retentate back to the source.

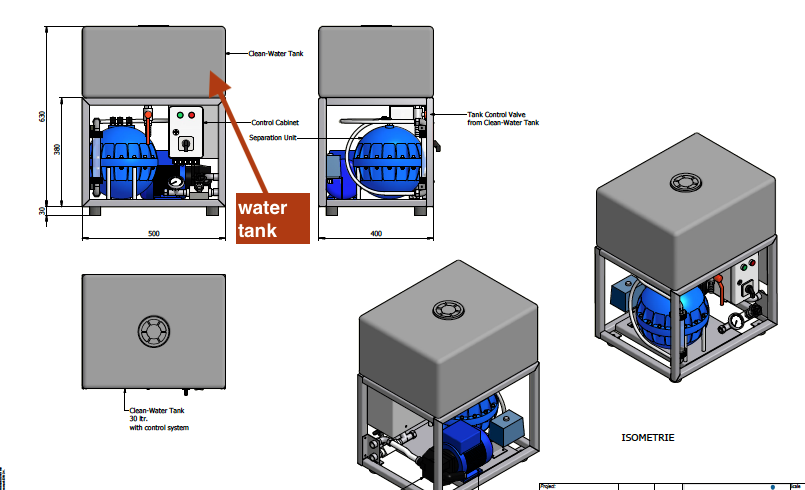

Structure of the system

The system consists of a membrane filter module, an electrically operated pump, and a reservoir for the drinking water. In addition, the system has sensor for the monitoring of fluid flow in the pump. The dry running of the pump is prevented by a flow switch.The system pumps the drinking water produced into a water tank which is equipped with level sensor for monitoring the liquid level.

The pump generates a fluid flow until the upper level sensor switch is reached. The drinking water can be taken until the pump is switched on by reaching the lower level sensor again. The pure water occurs as a result of pressure in the filter chamber through the membrane filter.

The system presented here requires a cross flow respectively of 300 l/h that automatically keep the membrane filter clean.

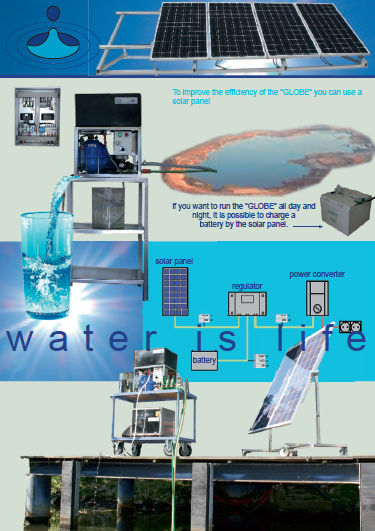

The SOLAR WATER PURIFICATION SYSTEM

A simple self-sufficient water treatment system into practice. The compact, mobile water treatment and desalination systems are powered using integrated hybrid solar . This means that there are virtually no boundaries to using this system anywhere in the world.

This system can run approximately 12 hours continuously using sunlight and 24 hrs with battery. This system will use a solar / battery powered 12 or 24 volt system to supply its primary power needs. Whenever the sun in shinning, the solar system will always be recharging the battery, even when the water treatment system is working. This system comes as a turn-key package. It is designed for easy installation.

To help citizens get drinking water during natural disasters,CALA CASA GROUP developed a portable water filtration unit. Named the Globe Solar Water System, the mobile unit will run on either solar power or batteries and can produce around 7000 liters of water per day. Key to the development of the unit is its Disc filtration System.

With global climate change making floods more frequent, countries that lay in floodplains or near sea level will have to begin developing the critical infrastructure to combat these events. The CALA CASA water filtration system is an excellent first step forward.

MOBILE BOTTLING CONTAINER FOR THE ARMY

Aquacontainer_Eng

BOTTLING-CONTAINER-SPECIFICATIONS

MODULAR-BOTTLING-CONTAINER-1

FULL-AUTOMATIC-MODULAR-BOTTLING-CONTAINER-1