Conventional seawater desalination

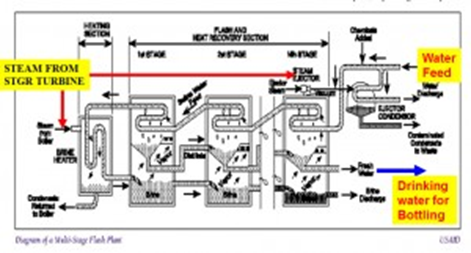

Conventional seawater desalination processes use electricity and/or steam from a conventional electric power station to produce purified water from seawater.

Three approaches to seawater desalination are considered :

- Reverse osmosis (RO)

- multi-stage flash distillation (MSF)

- multi-effect distillation (MED)

While there are other desalination technologies, these three represent the vast majority of the current market share:

- RO ~53%

- MSF ~25%

- MED ~8%

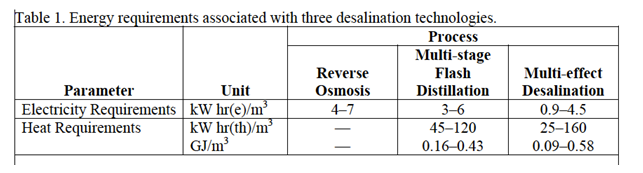

The energy requirement for each of these processes is shown in Table 1 (IAEA 2007).

RO requires energy only in the form of electricity.

MSF and MED require both electricity and heat to desalinate seawater.

Typically, purified water generated via the RO process has relatively higher residual total dissolved solids (TDS) than purified water generated via the MSF or MED processes.

In desalination plants that include both RO and MSF or MED systems, the water is blended to achieve the desired purified water product.

Climate independent source of drinking water

Cala Casa sets the standard for environment and sustainability stewardship in new water projects through design, construction and operation.

Specification:

- Capacity : 30 Ml per day

- Land : 50 Ha

- Concentrated solar power 25 MW

- Land : 25 Ha

- Solar driven supercritical power cycle

- Supported by Natural gas turbine Modules

- and the integrated super critical electric power conversion from the CSP.

Characteristics of the seawater desalination plant :

- Water intake ensures no impact on the aquatic environment

- No chemicals during the pre-filtration

- Use of Space tube RO membranes

- Reduced energy consumption by recycling the pressure

- Producing healthy potable water in bulk

- Bottled water produced at the desalination plant

- No brine discharge

- Sea minerals for agriculture and industry

- Purification of waste water

Seawater desalination plant on DBOO basis:

(Design, Build,Own and Operate) Cost of bulk water is in relation to the fuel price and is estimated between 0,5$US to 1,0$US per 1000 liter ex works. Bottled water in bottles of 0,5 liter to 20 liter on demand. Excess of electricity can be supplied to the grid or direct to consumers.

CALA CASA SL appoints Kriva Rochem

CALA CASA is a SPANISH-based company , a Designer and Promotor for Energy and Seawater Desalination solutions collaborating closely with experts in the fields of research, design, technology and construction management.The firm was founded in 1989.

Our company CALA CASA is linked with Kriva Rochem and their team of experts involved in the design and construction of numerous desalination plants based on membrane filtration and ion exchange.

The novel treatment and handling of brine recovers up to 90% potable water and a production of solid sea minerals is achieved.

The business Line Water Technology offers the full range of design, engineering , construction and supervision for delivering domestic and industrial water treatment plants.

Desalination capability

Desalination

SEA WATER TRANSFORMED IN DRINKABLE WATER

Desalination is a separation process used to reduce the dissolved salt content of saline water to a usable level. All desalination processes involve three liquid streams: the saline feedwater (brackish water or seawater), low-salinity product water and very saline concentrate (brine or reject water).

The saline feedwater is drawn from oceanic or underground sources. It is separated by the desalination process into the two output streams: the low-salinity product water and very saline concentrate streams. The use of desalination overcomes the paradox faced by many coastal communities, that of having access to a practically inexhaustible supply of saline water but having no way to use it. Although some substances dissolved in water, such as calcium carbonate, can be removed by chemical treatment, other common constituents, like sodium chloride, require more technically sophisticated methods, collectively known as desalination.

In the past, the difficulty and expense of removing various dissolved salts from water made saline waters an impractical source of potable water. However, starting in the 1950s, desalination began to appear to be economically practical for ordinary use, under certain circumstances.The product water of the desalination process is generally water with less than 500 mg/1 dissolved solids, which is suitable for most domestic, industrial, and agricultural uses.

A by-product of desalination is brine. Brine is a concentrated salt solution (with more than 35 000 mg/1 dissolved solids) that must be disposed of, generally by discharge into deep saline aquifers or surface waters with a higher salt content. Brine can also be diluted with treated effluent and disposed of by spraying on golf courses and/or other open space areas.

There are two types of membrane process used for desalination: reverse osmosis (RO) and electrodialysis (ED). The latter is not generally used in Latin America and the Caribbean. In the RO process, water from a pressurized saline solution is separated from the dissolved salts by flowing through a water-permeable membrane.

The permeate (the liquid flowing through the membrane) is encouraged to flow through the membrane by the pressure differential created between the pressurized feedwater and the product water, which is at near-atmospheric pressure. The remaining feedwater continues through the pressurized side of the reactor as brine. No heating or phase change takes place.The major energy requirement is for the initial pressurization of the feedwater. For brackish water desalination the operating pressures range from 250 to 400 psi, and for seawater desalination from 800 to 1 000 psi.

In practice, the feedwater is pumped into a closed container, against the membrane, to pressurize it. As the product water passes through the membrane, the remaining feedwater and brine solution becomes more and more concentrated. To reduce the concentration of dissolved salts remaining, a portion of this concentrated feedwater-brine solution is withdrawn from the container. Without this discharge, the concentration of dissolved salts in the feedwater would continue to increase, requiring ever-increasing energy inputs to overcome the naturally increased osmotic pressure.

A reverse osmosis system consists of four major components/processes: (1) pretreatment, (2) pressurization, (3) membrane separation, and (4) post-treatment stabilization. Figure 16 illustrates the basic components of a reverse osmosis system.

Pretreatment: The incoming feedwater is pretreated to be compatible with the membranes by removing suspended solids, adjusting the pH, and adding a threshold inhibitor to control scaling caused by constituents such as calcium sulphate.

Pressurization: The pump raises the pressure of the pretreated feedwater to an operating pressure appropriate for the membrane and the salinity of the feedwater.

Separation: The permeable membranes inhibit the passage of dissolved salts while permitting the desalinated product water to pass through. Applying feedwater to the membrane assembly results in a freshwater product stream and a concentrated brine reject stream. Because no membrane is perfect in its rejection of dissolved salts, a small percentage of salt passes through the membrane and remains in the product water. Reverse osmosis membranes come in a variety of configurations. Two of the most popular are spiral wound and hollow fine fiber membranes. They are generally made of cellulose acetate, aromatic polyamides, or, nowadays, thin film polymer composites. Both types are used for brackish water and seawater desalination, although the specific membrane and the construction of the pressure vessel vary according to the different operating pressures used for the two types of feedwater.

Stabilization: The product water from the membrane assembly usually requires pH adjustment and degasification before being transferred to the distribution system for use as drinking water. The product passes through an aeration column in which the pH is elevated from a value of approximately 5 to a value close to 7. In many cases, this water is discharged to a storage cistern for later use.

The capacity of reverse osmosis desalination plants sold or installed during the 20-year period between 1960 and 1980 was 1 050 600 m3/day. During the last 15 years, this capacity has continued to increase as a result of cost reductions and technological advances. RO-desalinated water has been used as potable water and for industrial and agricultural purposes.

If you would like to get some more information on the process of desalination, we are at your disposal.

WATER TREATMENT BY REVERSE OSMOSIS

DISC TUBE MODULE TECHNOLOGY

REVERSE OSMOSIS SYSTEMS

How does Reverse Osmosis work?

Pressure is applied to saline water to force the pure water molecules trough a semi-permeable membrane. The majority of the dissolved salts, organic material, bacteria and suspended solids are unable to physically pass through the membrane and are discharged from the system in the rejected brine. The pure water is then ready for use without further treatment.

The W.A.T. Disc Tube Module System – A major advance in Reverse Osmosis Technology.W.A.T.’s disc module technology has created major advances in the field of REVERSE OSMOSIS and its use in the desalination and purification of seawater, brackish water and city water.

The DT Module is a major advance from the plate module technology, which was originally developed by the West Germany Research Centre (GkSS).

The patented DT-Membrane-Module is a modern design for desalination and purification of liquids. It operates effectively and economically even at increased turbidity and Silt Density Index levels for reverse osmosis.

The successful development of the DT module was made possible by a precise technical approach in developing the total RO system. W.A.T. possesses the rare capability of being both the module manufacturer and the systems manufacturer. This dual capability, plus direct contact with the end user, is of great advantage to the customer.

Why is the W.A.T. DT Module System the best choice in RO?

Firstly, the patented fluid dynamics and construction of the disc membrane stack result in an open channel, unrestricted and fully turbulent feedwater flow system. This means that suspended solids carried in the feedwater cannot be trapped or easily settle out inside the membrane module. Most importantly it also means that the infrequent and highly successful maintenance cleaning of the membranes can be achieved using a standard inbuilt cleaning system.

Secondly, W.A.T. is commited to the use of components, materials and methods of design and construction of only the highest quality, to ensure for the end user 24 hours per day reliability and product water quality.

Advantages of the W.A.T. DT module RO System

Minimises membrane scaling and fouling. While the performance of other types of RO system can be limited by membrane scaling and fouling, the unique fluid dynamics of the plate system have resolved this problem to an easily controllable degree.

Simplified pre-filtration

The open channel W.A.T. RO OT modules can operate without problems on filtered sea water with a Silt Density Index (SOI) as high as 15-20. Other module systems specify SOI limits as low as 3, which require complex filtration and chemical treatments. SOI requirements of W.A.T. OT systems can easily be provided by simple sand and cartridge filters.

High recovery rates for low energy costs :

Up to 30% from seawater – energy costs average only 10 kWh/m3 of pure water.

Up to 75% from brackish water (TDS = 5.000 pip) – average 4 kWh/m3 of pure water.

Up to 85% from city water (TDS = 800ppm) – average 2 kWh/m3 of pure water.

These figures relate to standard systems so if brine energy recovery is also employed for seawater desalination energy costs can be reduced by as much as a further 50%.

No chemical operating costs.

Unlike other RO systems the W.A.T. OT module technology means that no permanent feedwater pretreatment with acid is required at sea water desalination.Long membrane life.

The combination of low membrane scaling and fouling, highly stable membranes and a simple and effective built-in cleaning system means that membrane life-expectancy is not normally limited by feedwater pollution in the W.A.T. system. Useful membrane life of 5 years or more has proved to be a realistic figure.

Lower membrane replacement costs

In traditional systems, spirally wound and hollow fine fibre membrane elements are life-sealed at manufacture so the complete element must be replaced at relatively high cost. The OT module system offers the possibility of replacing individual sheets of membrane at a fraction of the cost.

Easy access to all membranes

Modules can easily be opened up to permit exchange or inspection of each membrane cushion. This is very difficult on other types of RO modules.High quality product water / Latest membrane technology Standard W.A.T. RO systems use the latest technology, chemically stable, thin film composite (tfc) membrane materials. In addition, the use of membranes in sheet form means that we can select and accurately control the quality of the installed membrane to ensure minimal salt passage to consistently produce high quality permeate.

Fail-safe unattended operation

The only moving part in the system is the pump and all operating functions are automatically controlled and failsafe. No special skills are required to operate the system.

Compact and flexible modular units

The truly modular design and construction of all standard W.A.T. RO units simplifies transportation and installation and enables flexible use of limited floor space.

W.A.T. REVERSE OSMOSIS SYSTEMS

RO MEMBRANE FILTRATION UNITS

Designed and constructed for continuous operation to desalt and purify:

RORO 200. from sea water:

2.000-4.000 l/24h

potable water

RORO 510. from sea water:

5.000-10.000 l/24h

potable water

SEA WATER – BRACKISH WATER – CITY WATER

With comprehensive standard features

Features such as filter booster pump, filtration package, builtin cleaning system, automatic pressure regulation, flow control, full instrumentation and fail-safe protection are fitted as standard, and not as expensive though necessary ‘options’ as in the case of many other systems.

And additional facilities

The basic system design allows for a building block concept or modular expansion to incorporate – either at the factory or as a later retrofit – additional facilities to meet the changing needs of the operator. For example raw water pre-heaters can be included with no modifications to the basic system. Carbon filters, pure water distribution systems, ultra violet and/or chlorine dosing systems, etc. can also be easily interfaced with the basic system.

Plus low-cost maintenance, operation and service

Modular construction and purpose-designed clear access to all major components and piping means that inspection and preventative maintenance can be carried out quickly and effectively.

Automatic operation and regulation of the system, fail-safe design and fault indication facilities ensure correct, safe and reliable operation of the system.A fully documented computer ‘history’ with details of all component parts used is developed for each system produced and a comprehensive spare parts and consumables inventory is maintained by W.A.T. to provide the operator with a quick response after-sales service.

Based wide range of standard systems

With 20 different capacities up to 300.000 litres/24 hours for sea water application and a similar number up to 700.000 litres/24 hours for brackish water. W.A.T. can usually meet at short notice most customer requirements from its standard range. If not, larger capacity systems, or more specialized systems, are available on request.

And installed and operational in a matter of hours since every W.A.T. RO system is completely assembled and fully tested prior to dispatch from the factory and can be in full operation literally just a few hours after arriving on site as there are only four fixed or flexible pipe connections to make plus an electrical supply. Nothing else.

List of standard components:

- Filter booster pump

- Sand filter or carbon filter

- Cartridge filter

- High-pressure pump system

- High-pressure control system

- RO DT module permeators

- Pure water deacidification filter

- Inbuilt closed circuit cleaning system

- Automatic pure water membrane flushing system

- Power and control system with microprocessor

- Full instrumentation and measurement equipment

- Comprehensive fail-safe system

- Fault indication

- Modular skid frame construction

- Optional Equipment

- Main raw-water supply pump

- Submersible well-water supply pump

- Pure water tank and distribution pump

- Chlorine dosing system

- Ultra violet disinfection system

- Containerised / mobile systems

- Self contained power supply

- Shock and vibration proof systems to military standards

- non-magnetic systems

RORO 1530. from sea water:

15.000-30.000 l/24h

potable water

RORO 3560. from sea water:

35.000-60.000 l/24h

potable water

DT-Membrane-Module system

The patended DT-MEMBRANE-MODULE is a modern design for molecular separation, desalination and purification of liquids. It can operate effectively and economically at increased turbidity and Silt Density Index levels for ultra-filtration and reverse osmosis.The disc-membrane stack is assembled on the center tension rod with metal end flanges. The module stack is covered in an open, standard 8 inch pipe The feed water is sealed by a pressure flange seal. The pressure vessel design allows for an easy alteration of module length and tube materials.

The special modular construction facilitates inspection or changing of membranes in a quick and easy manner. This further facilitated by lightweight construction and materials.

The disc-membrane stack operates at pressure compensation (feed to brine). The special hydraulic characteristics ensure safe operation at each pressure stage and at high pressure drops.

The hydraulics result in a high flow velocity across the membranes at minimum feed flow. The open feed channel over the membrane surfaces ensures optimal membrane cleaning from fouling deposits.

Hydraulic Disc

The standard hydraulic disc is manufactured from the material ABS, Different materials are available for special feed quality.

The disc covers the membrane cushion without putting pressure on the membrane surface.

The feed water is sealed with an o-ring from the pure water manifold in the center of the tension rod. The membrane spacer and the permeate manifold are designed as an integral part of the hydraulic disc. The integrated spacer forms the open feed water channel.

Membrane Cushion

The membrane cushions are sealed by ultrasonic welding.

This welding technology has been proven over several years in different applications and with different membrane types,

The extremely short feed water path across the membrane followed by an 180 degree flow reversal eliminates polarization concentration. Consequently, the DT-Membrane-Module results in minimum membrane fouling and scaling. The permeate drains from the cushion’s intermediate layer into the manifold with minimum flow path and minimum resistance.